Additional

Drawings, Schedules and Specifications

While a Power System One-Line is the basis for defining the

interrelationships between the various types of distribution equipment, there

is often more information that needs to be conveyed.

Because the end loads and

the conductors feeding them are the basis for proper selection and application

of the circuit breakers, a valuable step in the selection process is developing

a schedule.

The overcurrent protection of many loads, such as motors and distribution

transformers, must conform to the requirements of Articles 240, 430 and 450 of

the National Electrical Code. Particular consideration needs to be given to the

length and type of conductors that will need to connect the distribution

equipment.

As cable length increases, so does its resistance in the circuit

leading to a drop in the voltage at the end of the conductor run feeding the

loads. Cable lengths exceeding 100 feet generally need to be upsized to offset

for voltage drop concerns.

Cable length, size and the raceway they are

installed in, also have an impact on the impedance of the conductor in the circuit.

Greater impedance helps to reduce the available short circuit at the terminals

of the distribution equipment or end load.

The 310.15(B) (3) from the National Electrical Code defines the

Allowable Ampacities of Insulated Conductors rated 0-90 degrees C. While

details of this table are included in the reference section of this chapter, it

should be noted that Listed Distribution Equipment is provided with terminations

rated at 75 °C.

From a pragmatic standpoint, this means that the equipment

could be fed from conductors rated at either 60 °C or 75 °C. Derating would be required

for the conductor ampacity at 60 °C making it less practical. It also means

that the equipment could be fed from 90 °C conductors, but only if applied at

the 75 °C ratings due to the limitations of the equipment ratings.

The

following tables are adjusted in accordance with NEC 240.4(D) to show the

actual allowable ampacities of copper and aluminum conductors terminating in electrical

distribution assemblies.

A schedule based on the allowable ampacity of copper

conductors in Table 1.1-1 is

shown in Figure 1.1-19.

It includes the relevant requirements for secondary unit substation “SUS-F1A” shown

on the One-Line. This schedule outlines the breaker frame sizes, trip settings

and particulars of the trip units required.

It also annotates the names for the

breakers as well as their circuit nameplate designations. The cable sizes and

quantities are determined by utilizing the tables in the NEC, (as condensed

into Table 1.1-1).

The

equipment ground sizes are per NEC Table 250.122 based on the trip rating of the

overcurrent device protecting the phase and neutral conductors. Note that they

do not take voltage drop into consideration.

|

| Table 1.1-1. Ampacity of CU Conductors |

Table 1.1-2. Ampacity of AL Conductors

|

Figure 1.1-19. Unit Substation Cable Entry Position

In

order to provide an effective ground fault path as required by 250.4(A)(5) and

250.4(B)(4) of the 2014 NEC, upsizing of the equipment ground conductors are

required by Article 250.122(B) “when the ungrounded conductors are increased in

size from the minimum size that has a sufficient ampacity for the intended

installation”.

In these cases, “wire-type equipment grounding conductors, where

installed, shall be increased in size proportionally according to the circular

mil area of the ungrounded conductors”.

When developing schedules, it is

important to remember that conductor sizing is also impacted by the derating

tables for ambient temperature and conductor fill when installed in raceways.

There

are a number of ways to create cable schedules, the most common of which is to

name the conductor as is shown on the medium voltage portion of the One-Line in

Figure 1.1-2. Schedules are most often used to define requirements for

low-voltage switchboards and panelboards. They may also be utilized to enumerate

the various automatic transfer switches and the cables connecting them to the

normal and emergency sources as well as the end load. Other drawings that are

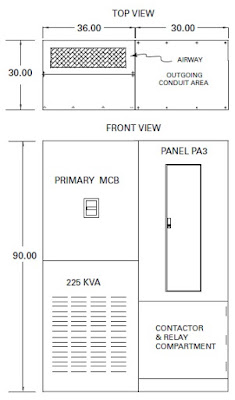

necessary to produce the installation package are floor plans that include room

dimensions, equipment locations allocated within the space, appropriate

clearances per code requirements and means of egress from the area where the

equipment is located. These drawings have been done primarily in 2D CAD programs

with boxes showing equipment dimensions on the floorplan. A front view of the equipment

is also used to detail the elevation requirements. Equipment occasionally

requires top hats or pullboxes that add height above the switchboard or

switchgear. On other occasions, the room does not have enough height to

accommodate standard equipment. In these cases, special reduced height

switchboards or switchgear may be provided. While this equipment may not be documented

as standard, Eaton can provide assistance in developing a reduced height

alternative solution.

As

design and drafting tools have evolved, the push to include 3D drawings has

subsequently evolved into an enhanced technology called Building Information

Modeling (BIM). BIM drawings include the 3D aspect but also include the capability

to assign equipment performance parameters and interdependencies. This permits

architects and construction firms to be alerted to potential “collisions”

between incoming/ outgoing conduits and other potential obstructions such as

existing conduits/ busduct, HVAC duct or plumbing in the space above or below

the equipment.

|

Figure 1.1-20. Equipment Floorplan and Elevation

|

Figure 1.1-21. BIM 3D Model Top View

No comments:

Post a Comment